Sehlahisoa

Stainless steel bundle fiber kapa textile inner core conductive terata bakeng sa masela a futhumetseng

Tlhaloso ea Sehlahisoa

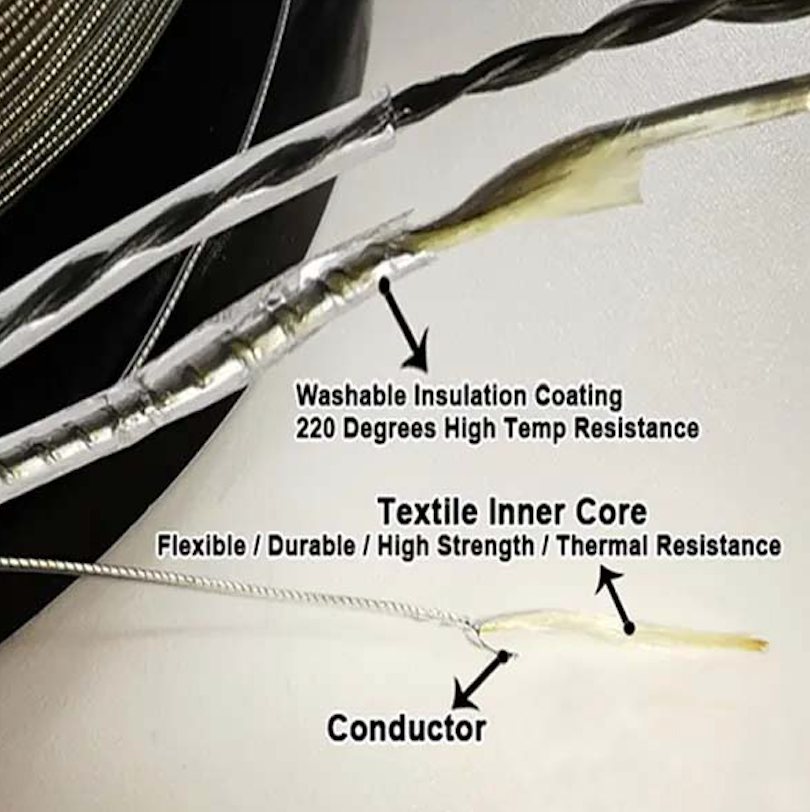

1-Stainless steel fiber based bundle moo bophara ba fiber e 'ngoe le e 'ngoe e leng 12µ kapa 14µ. Boholo ba likhoele hangata bo fapana ho tloha ho tse 200 ho isa ho tse fetang 1500. Sena se u fa durability e leng 'ea molemo ka ho fetisisa sehlopheng'. Ka lebaka la likhoele tse ntle tse sebelisoang, likhoele tsena li ntse li le tšesaane ka bophara ka kakaretso 'me kahoo li tenyetseha haholo ha li sebetsa.

2-Re koahela mefuta e mengata e fapaneng ea ho hanyetsa ka tlase ho terata e ntle e eketsehileng le likhoele tse nyane tse nang le litšobotsi tse tšoarellang le tse tenyetsehang, tse khethehileng tsa rona tse nang le masela a ka hare a masela a manyane a ka tiisa khanyetso ka mitha e 'ngoe eo u e hlokang mme e u fa phetoho e eketsehileng moralong empa e ntse e fana ka boleng bo holimo. flex-bophelo hofeta dithapo tse tlwaelehileng. Ho ipapisitsoe le alloy e phuthetsoeng ka ntle e ka kenngoang, koporo, alloy ea silevera, joalo-joalo, re ka hlahisa likhoele tse sa sebetseng hantle tse ka tlase ho 1 ohm/m ka mefuta e le 'ngoe le e koetsoeng ho latela tlhoko ea bareki.

Textile ka hare konokono micro cables melemo

Khanyetso e Kobehang

Ka lebaka la sebopeho le motsoako oa lisebelisoa, terata e na le khanyetso e babatsehang ea ho koba.

Ho tenyetseha

Lithapo tse nyane li sebelisa foil ea tšepe e tšesaane haholo joalo ka conductor, e hlokomelang maemo a bonolo haholo.

Haholo-holo

Ka mor'a extrusion thapo ea rona e nyane e nyane haholo e ka ba 0.35mm.

Matla a Matla a Phahameng

Re sebelisa likhoele tsa Aramid / Liquid Crystal Polymer le li-self engineer high tech fibers.

Mocheso o Phahameng. Khanyetso

Re sebelisa likhoele tsa aramid kapa stanless steel bundle bakeng sa likhoele, mocheso o phahameng o hanyetsana ho tloha ho likhato tse 230 ho isa ho likhato tse 580 bakeng sa khetho ea hau.

Ho qeta & ho roala

Lefats'eng la hau, ho na le tlhokahalo e kholo ea ho roala likhoele ka bomong kapa ho roala ka kakaretso holim'a thapo e felletseng. Hape re ka etsa joalo, likahare tsa rona tsa extrusion li kenyelletsa FEP,PFA,PTFE,TPU joalo-joalo.

TLHALOSO JAKE JAKE

| Extrusion | TPE | FEP | MFA |

| Melting Point | 205° C | 255° C | 250° C |

| CTs'ebetso e tsoelang pele TEmperature | 165° C | 205° C | 225° C |

Li-bundle tsa Stainless Steel Fiber

Textile Inner Core Micro Cable Constructions

Thehiloeng Embroided Heating Element

Lisebelisoa tsa tšepe tse sa hloekang li kopanya mefuta e fapaneng ea ho hanyetsa bakeng sa litšupiso tsa hau.

| Diameter (um) | Li-filaments | Matla (cN) | Boima ba 'mele (g/m) | Elongation (%) | Conductivity (Ohm/ m) |

| 8 | 1000F x 1 | 69 | 0.420 | 1.10 | 16 |

| 8 | 1000F x 2 | 108 | 0.850 | 1.10 | 8 |

| 12 | 100F x 1 | 24 | 0.110 | 1.10 | 59 |

| 12 | 100F x 2 | 41 | 0.190 | 1.10 | 38 |

| 12 | 100F x 3 | 69 | 0.280 | 1.10 | 22 |

| 12 | 257F x 1 | 59 | 0.260 | 1.10 | 27 |

| 12 | 275F x 2 | 75 | 0.540 | 1.10 | 14 |

| 12 | 275F x 3 | 125 | 0.780 | 1.10 | 9 |

| 12 | 275F x 4 | 130 | 1.050 | 1.10 | 7 |

| 12 | 275F x 5 | 160 | 1.300 | 1.10 | 5 |

| 12 | 275F x 6 | 180 | 1.500 | 1.10 | 4 |

| 12 | 1000F x 1 | 100 | 0.950 | 1.10 | 7 |

| 12 | 1000F x 2 | 340 | 1.900 | 1.10 | 4 |

| 14 | 90F x 2 | 46 | 0.190 | 1.10 | 44 |

| 14 | 90F x 1 | 25 | 0.110 | 1.10 |

Textile ka hare konokono conductive terata mefuta e fapaneng ya ho hanyetsa

| Mokhanni oa Kantle | Textile Inner Core | Diameter mm | Boikhantšo ≤Ω/m |

| Koporo 0.08mm | 250D Poyester | 0.20±0.02 | 6.50 |

| Koporo 0.10mm | Polyester ea 250D | 0.23±0.02 | 3.90 |

| Koporo 0.05mm | 50D Kuraray | 0.10±0.02 | 12.30 |

| Koporo 0.1mm | 200D Dinima | 0.22±0.02 | 4.00 |

| Koporo 0.1mm | Polyester ea 250D | 1*2/0.28 | 2.00 |

| Koporo 0.1mm | 200D Kevlar | 0.22±0.02 | 4.00 |

| Koporo 0.05mm | Polyester ea 50D | 1*2/0.13 | 8.50 |

| Koporo 0.05mm | Polyester ea 70D | 0.11±0.02 | 12.50 |

| Koporo 0.55mm | Polyester ea 70D | 0.12±0.02 | 12.30 |

| Koporo 0.10mm | K'hothone 42S/2 | 0.27±0.03 | 4.20 |

| Koporo 0.09mm | Polyester ea 150D | 0.19±0.02 | 5.50 |

| Koporo 0.06mm | Polyester ea 150D | 0.19±0.02 | 12.50 |

| Koporo ea Tin 0.085mm | 100D Kuraray | 0.17±0.02 | 5.00 |

| Koporo ea Tin 0.08mm | 130D Kevlar | 0.17±0.02 | 6.60 |

| Koporo ea Tin 0.06mm | 130D Kevlar | 0.16±0.02 | 12.50 |

| Koporo ea Tin 0.10mm | Polyester ea 250D | 0.23±0.02 | 4.00 |

| Koporo ea Tin 0.06mm | Polyester ea 150D | 0.16±0.02 | 11.6 |

| Koporo ea Tin 0.085mm | 200D Kevlar | 0.19±0.02 | 5.00 |

| Koporo ea Tin 0.085mm | Polyester ea 150D | 0.19±0.02 | 6.00 |

| Silver Copper 0.10mm | Polyester ea 250D | 0.23±0.02 | 3.90 |